3d Rendering

When it comes to marketing and product promotion, presenting the product with clarity and effectiveness is extremely important. We know that you want it to shine like when you first envisioned it.

The product image you market speaks a thousand words, and by using photorealistic 3d rendering we are able to show your product in the best light possible.

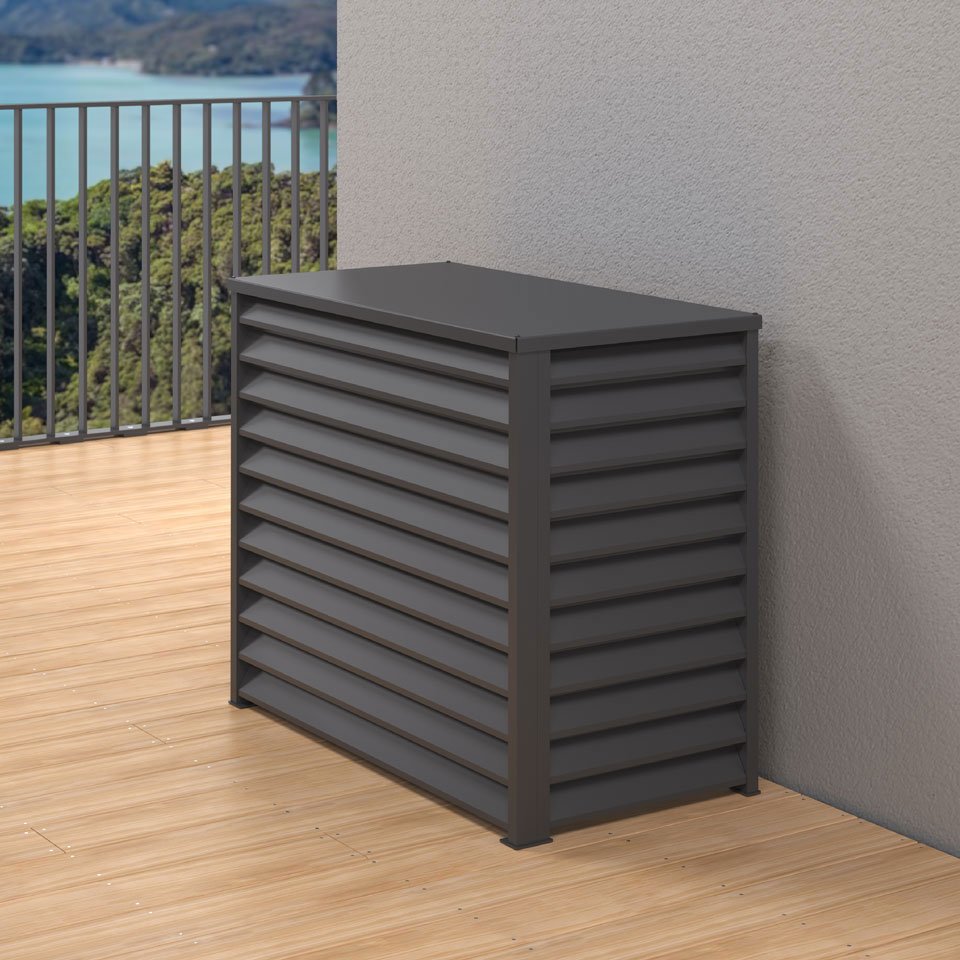

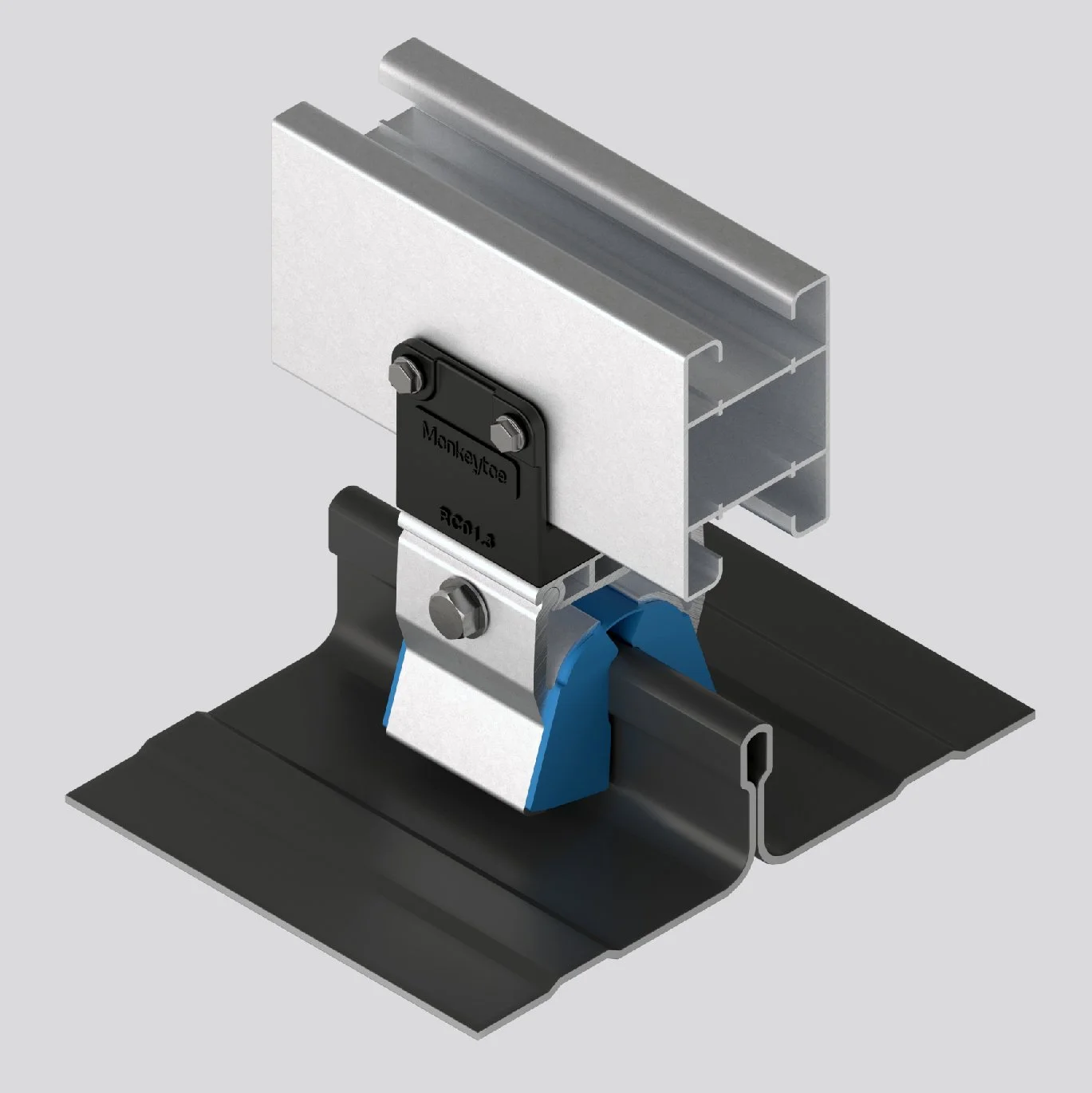

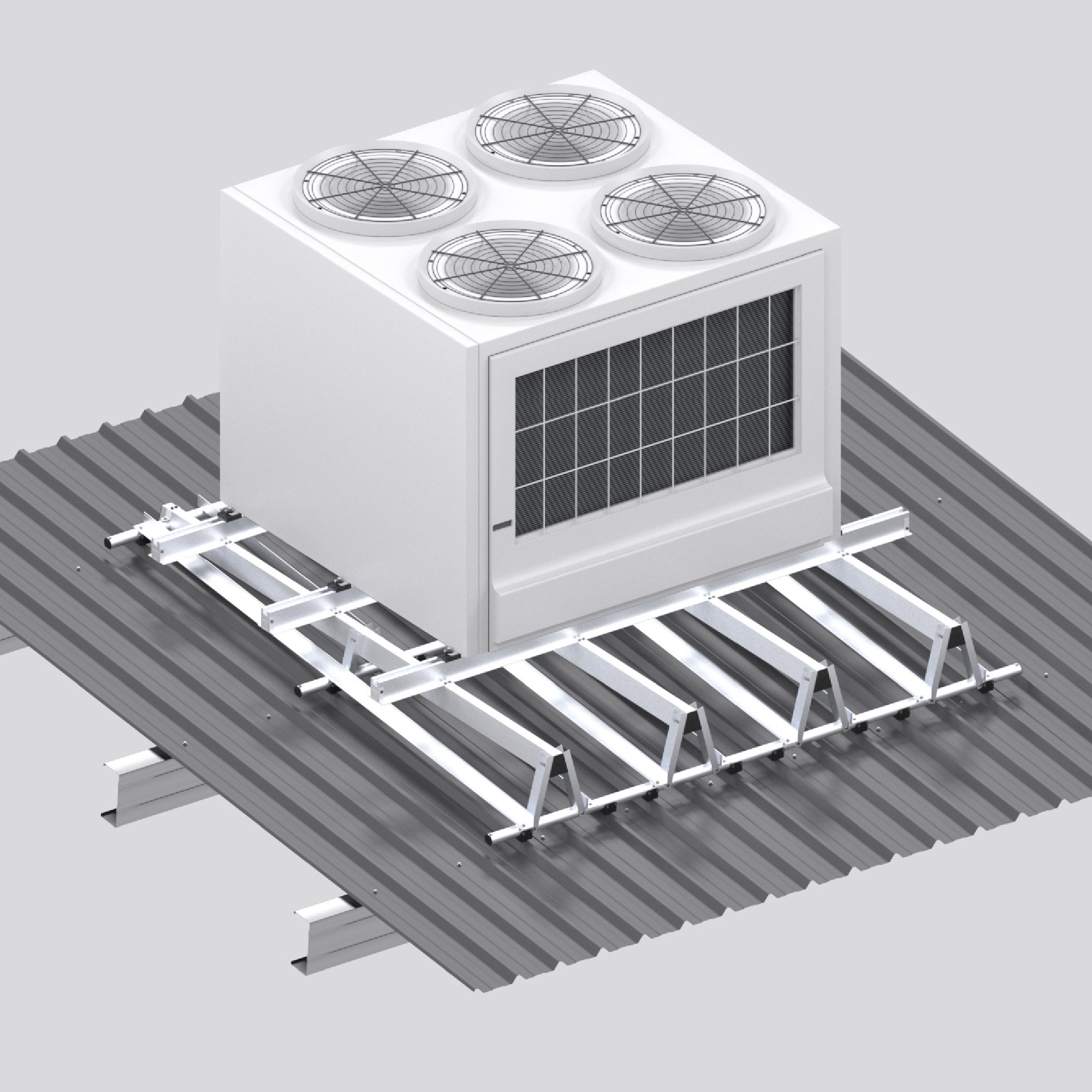

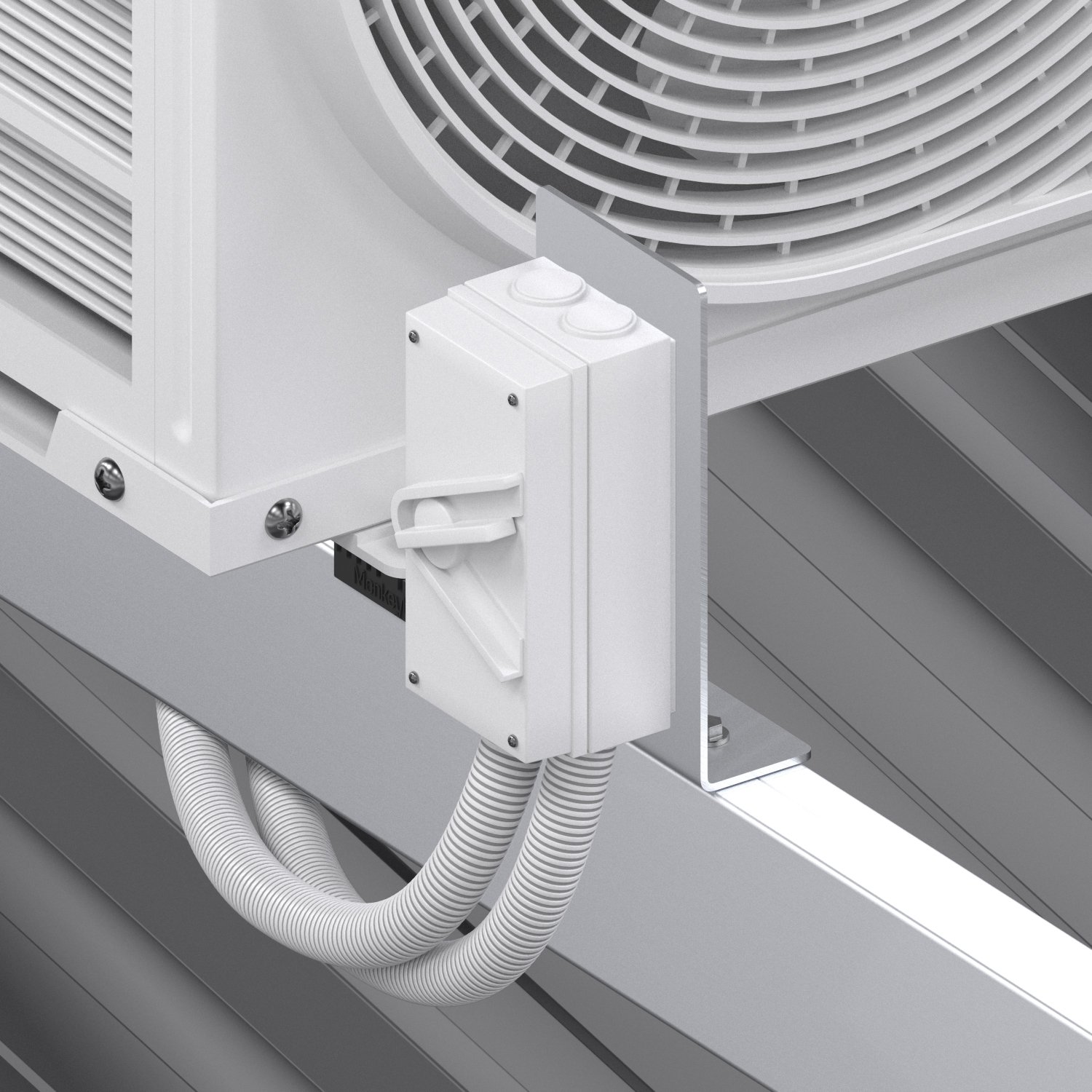

MONKEYTOE MOUNTING SYSTEMS

Monkeytoe Group produce a large variety of mounting systems for building applications and needed a way to communicate shape, scale and utilization of products to their customers.

A brand that is trusted worldwide by architects, engineers and building owners, Monkeytoe needed high quality visualisations of their products to reinforce the image already established and to stand out from competitors.

The most important factor in this project was to create the ability for the customer to visualise a sense of scale, between the available products, to better communicate their shape, scale and application. With a large catalogue of products, of all shapes and sizes, the best way to communicate the relative shape and scale of the products was to create the visualisations in orthographic view, as this keeps all the products dimensions consistent and eliminates lens warpage.

A physical camera is unable to capture a scene in orthographic view but we are lucky enough that ray trace renderers have broken the mold and only recently been able to produce realistic graphics within an orthographic format. The addition of a human scale within the shots also reinforces the scale of the products along with the consistent modeling of the products parts and realistic materials.

The whole projects pallet was contained within a small group of materials, with the most important material being the aluminium, the basis to most of their products. A scientifically perfect aluminium material was sourced and the results speak for themselves.

CLOTH BASED PRODUCT SIMULATIONS & RENDERING

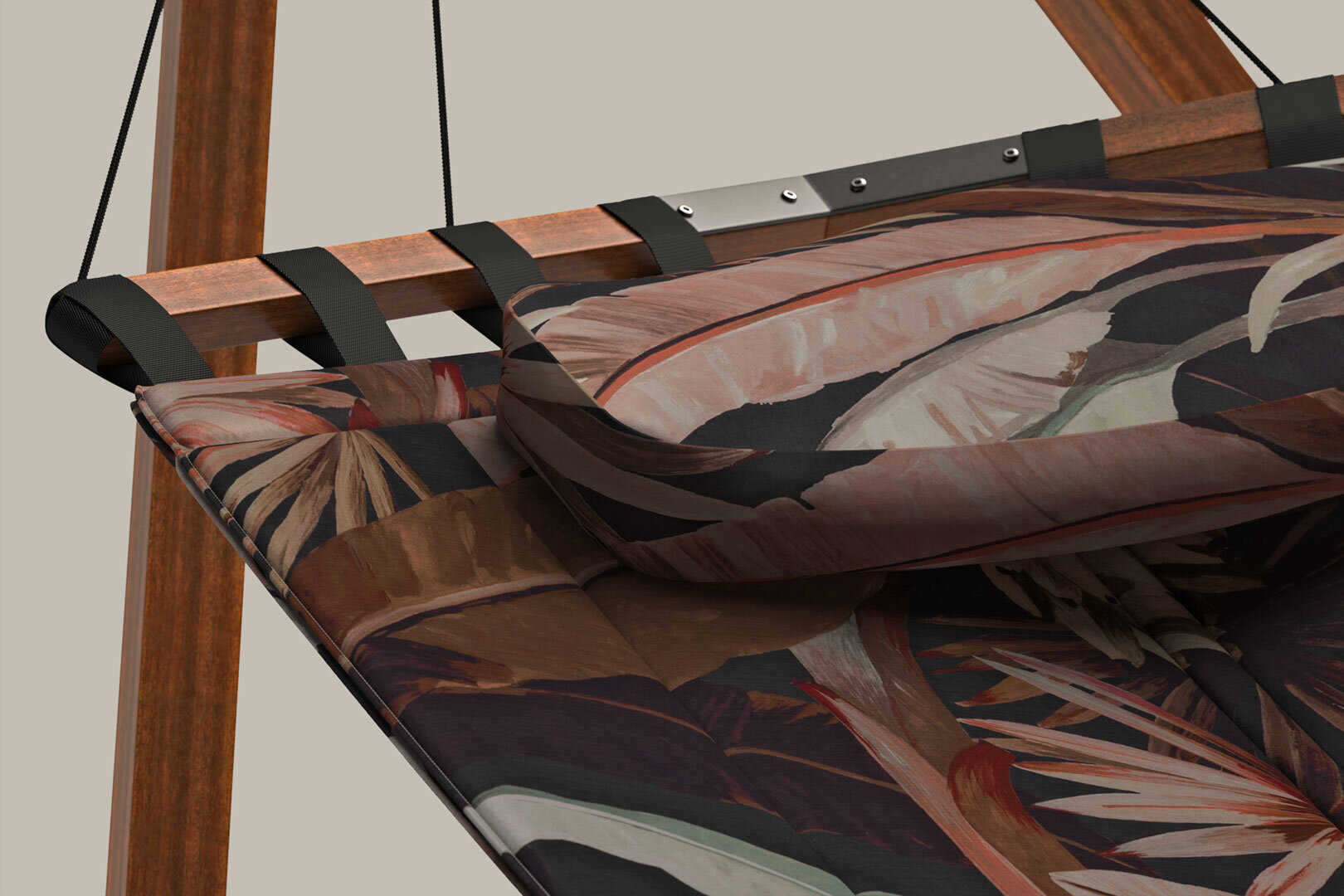

Lujo New Zealand a luxury hammock brand required 3d renders to show what their hammock products would look like with a variety of different fabrics sourced from James Dunlop Textiles. Using the Tropicalia print by Catherine Martins meant that Lujo couldn’t just manipulate the colours of older photo shoots (which was their previous technique) due to the prints complex illustrations.

3d rendering has allowed Lujo to show concepts of different fabrics without having to commit to producing physical examples of each colour way. It also reduced the need to have each variation individually studio photographed. Producing consistent results using 3d rendering is easy to achive compared to studio photography, especially if there is a decent timeline between product shoots. You can guarantee consistent result even many years down the track when utilising 3d renders for product visualisation.

With reasonably cheap set-up costs to create the base 3d model of the hammock and stand, Lujo are now able to quickly visualise a myriad of different styles and colours without the usual costs associated with generating similar marketing images.

In creating a believable result of a hammock in 3d, it was important to concentrate on how the fabric and construction held itself together. To achieve this we constructed the hammock within the cloth simulation program CLO3D. The nature of the hammock being filled with foam made the process more difficult to replicate. Pairing the geometry with high resolution seamless textures created a fantastic result. The template scene can now be used over and over again producing cost effective visualisations of any new fabric design. A great investment for the company.

PROFAB ENGINEERING CATAMARAN RENDERING

Profab Engineering build custom aluminium water crafts for local and international clients and are renown for innovation and quality. Profab were endeavouring to build a collection of 12m catamarans for the more pleasure craft style market and wanted to advertise their product before any were fabricated. The catamarans were designed by well renowned yacht designer Roger Hill and were needing to look luxurious and appeal to professionals.

It is one thing to create realistic graphics of a product, but to then have the product be placed into a natural environment is another. It was essential to show the boat in the ocean, which meant creating 3d wave geometry. Luckily there have been advances in this in recent years and we were able to take advantage of the wave simulator Maxwell Sea to create realistic waves and water reflections. This aided immeasurably to produce a believable result.

WETSUIT PRODUCT VISUALISATIONS

Ruby Fresh Wetsuits are an innovative product for fresh water activities where the suits construction has been tuned for buoyancy when used within lakes and rivers.

The geometry of the garments, male and female versions, were created using a fabric simulator called CLO3D. Where patterns can be virtually sewn together, draped and fitted over a digital mannequin. Multiple variants from the exported 3d model are then rendered solely by changing the materials of the panels within a secondary 3d program and renderer. This allowed us to dial up and down the thickness of each panel along with colours and graphics to create multiply styles all from the one, male and female, master 3d model.

Reproducing fast consistent imagery of all/new variants cheaply. An expensive job if reliant on traditional studio photography.

A recent change in manufacturing supplier, with subsequent graphics and pocket changes, RubyFresh have been able to acquire a new set of product renders with minimal cost to update their website with.

PBI HEIGHT SAFETY GRAPHICS

PBI Height Safety relies on 3D renders to showcase their diverse range of products and services. These offerings are often utilized in large-scale scenarios, posing challenges when it comes to capturing them through traditional photography methods. By embracing the 3D approach, PBI ensures the creation of visually cohesive imagery and attains the ideal angles to effectively capture and communicate the intended functionality of their products.

UNEX – ALUMINIUM BALUSTRADE SYSTEMS

UNEX - Aluminium Balustrade Systems sought polished and uniform visualisations for their product catalogue, ensuring clarity and consistency throughout. Employing a unified platform across scenes facilitated seamless visualisation of scale across their product range. A specific request was for the posts to be perfectly parallel, a feat accomplished by Immersive through the use of virtual shift lenses in their workflow, avoiding distortion that a normal camera lens might introduce. Additional 3D renders were commissioned to depict products within lifestyle scenarios, offering a glimpse into their application in real-world settings. The ability to showcase their products in exclusive locations is invaluable to UNEX, and Immersive tailored the visualisations precisely to their needs, maintaining both consistency and cost-effectiveness.

THIRD ISLAND - RAKIURA DISTILLING COMPANY

Rakiura Distilling Company, based in Stewart Island, wanted high-quality 3D renders to showcase their premium Gin and Vodka Third Island products in a visually striking way. In the competitive world of luxury spirits, the presentation of a product plays a key role in its success. To position Third Island Gin and Vodka as serious contenders in the market, it was essential to create renders that matched the sophistication and elegance of their competitors' visuals. The result is a set of sleek, polished 3D images that elevate the brand and highlight the craftsmanship of their product.

Creating professional liquor bottle visuals with traditional photography comes with inherent challenges. Transparency, reflections, and lens distortions caused by the bottle’s shape can lead to less-than-ideal results. With luxury bottle 3D rendering, these imperfections can be precisely controlled, allowing for refined, flawless images that showcase the product at its best.

AMPHIBIOUS VEHICLE PRODUCT RENDERS

Sealegs wanted a way for customers to see what their custom design craft will look like before construction. Sealegs pride themselves in the customisation of the product/services they offer, and due to this, showing a customer what they are going to receive before sale was complex and confusing. Using 3d rendering to visualise their one off products is very advantageous for them when negotating a sale.

Being supplied high polygon geometric models from the client, applied with physically correct materials and lighting allows for some spectacular, brand defining, imagery.

These 3d models were placed within a landcscape scene with the end goal being that new iterations of their crafts can easily replace the old within the template scene when new renders produced.

Different features, colours and upgrades can all be customised into the render allowing both partys to have a clear indication visually of what the craft entails.

It’s something to see your craft, in your chosen colours just as you envisioned it, sitting there in the surf as if it was real. Letting you know that yes, it is a good decision to proceed with the order.

CLOTHING VISUALISATIONS

3d clothing visualisations for Subtle Recordings website.

The geometry for the clothing was created using the garment simulator CLO3D. A program designed for the specific task of simulating fabric to aid in fashion design. The 3d models created in CLO3D can be exported to another program more suited to materials and rendering.

The combination of CLO3D’s very high detailed geometry (sewing treads) the natural folds and shaping it simulates, with the high detailed ray trace materials of Maxwell Render creates a very realistic result.

The frozen geometry can be rendered from any angle allowing for viewing of every side with consistent lighting. Changing the colour of the material and design of the graphic gives you the ability to create never ending variations with consistent results.

360° animations and faux moving 3d graphics can be implemented into websites and online branded advertising.

PANASONIC KITCHEN TEMPLATE

Lemonade Design Ltd required a 3d render to show their clients products interacting in a modern kitchen with the ability to swap-out between a variety of products.

The renders were also needed to be printed on billboards. 3d rendering allows for the creation of any size image.

The virtual camera within the modelling software can be tuned to any type of lens including tilt and shift. A shift lens was used to take this render. The ability to adjust the composition, framing and field of view without tilting the camera up or down (which would induce skewed vertical lines) is the largest benefit.

Architects love this feature as it visually communicates design features better and allows for better understanding of shape and volume of large objects.

Real world shift lenses are an expensive tool which would reflect in a specialised shift lens photographers fee.

HIGH SPEED DOORS

Ulti Group Ltd wanted to show consistent images of their products to better communicate the differences between them to their customers. And for the customers to see what the product entails without any other factory clutter which can confuse their application.

Ulti Group’s High Speed Doors are quite large making it difficult to capture using a camera. 3d rendering has allowed for a better camera angle, one that is usually obscured if taken in a traditional way, creating a better sense of the scene and products. It has also made the products look consistent which is usually impossible to achieve as photos would usually be taken within a variety of buildings all with different lighting and material colours.

3d rendering has also helped communicate the size between the doors allowing the customer to quickly see which product fits their needs.

INTERIOR VISUALISATIONS

The purpose of this render is to have the final product supplied as an editable Photoshop file that a design studio could manipulate to show different styles of carpet within the interior shot without having to re-render. Saving time and money for the design studio, who can produce many iterations for their client to approve.

The Photoshop template file supplied lets the user change the carpet by pasting a new one into it’s smart layer. Once saved the template file will integrate it into the render and apply all the shadows and lighting to create a realistic image of an interior.

Created using Maxwell Render Multilight, the final render saved from the program is split into a layer for each light source. Using 32bit colour in Photoshop adds all the individual lights sources together to reveal a completed render. Combine this with the alpha channels produced by the renderer aswell, and you have a realistic 3d render that can be manipulated by a Photoshop technician. Changing the carpet colours, furniture colours, all to compliment each other. Every light emitter within the scene can be dimmed or brightened within Photoshop giving the user the ability to fine tune their desired result.

SEISMIC PIN VISUALISATION

3d render of Onguard Seismic Systems Seismic Pin product that protects large wine vats during an earthquake. 3d rendered to show the product in the best light and perfect stainless steel material which shows no machining defects.

The advanced ray tracing technology which forms the core of the render software we use is so powerful that it is capable of simulating light exactly as it is in the real world. No tricks. Just real world physics. This means predictable, reliable first-time results. Speeding up the production of your product visuals transfers to waiting times and over-all price.

PRODUCT RENDER

An example render of an Omega Speedmaster Professional 'Moon Watch', the first watch worn on the Moon, for product visualisation and marketing purposes.

Marketers are constantly looking for eye-catching graphics for their brands social media campaigns. 3d renders communicate the dream of a company and demonstrate the product in it's most perfect light.

Custom geometry and materials create a imperfectionless model of the product allowing for a flawless result even when close-ups and micro photography shots are required.

EASY CONFIGURATOR CONTENT

Rendered for use in product visualisation. Separate colour designs were rendered which gave a professional and consistant representation of the product within a catalogue.

The benefit of seeing how a product will look before a prototype is manufactured is invaluable. There is only so much mental visualisation and comparing of swatches can do to represent a true result. 3d rendering can give you the confidence in going forward with production and a cheap way to see a myriad of combinations.

UNDERSTANDING THE RENDERING PROCESS

This render is an example to show the process of creating 3d Renders, for use inhouse for us, Immersive Reality Limited.

We found that one of our biggest barriers in business is educating client's on the process, possibilities and inherent costs of producing photorealistic 3d renders.

This visual is an example showing how simple it is to change the material of a model into a variety of different materials and textures. All its takes is another render, and you can have a new variation of a product. The render cost is not determined by what changes have been made to the model but from how long the render takes to be Calculated and completed. Transparent materials or lots of light emitters can increase render times exponentially, due to the more passes requiring calculation to achieve a satifactory 'sample level' so as to not see any grain within the final image.